Want better forecasts? Start tracking bias. Tracking signals are simple tools that help businesses identify and fix errors in their forecasts. By comparing cumulative errors to average deviations, tracking signals highlight when predictions consistently lean too high or too low. This helps prevent costly mistakes like overstocking or running out of inventory.

Key Takeaways:

- What is it? A tracking signal flags forecast bias by monitoring cumulative errors.

- Why use it? Companies using tracking signals report up to 67% better accuracy and 60% higher profitability.

- How does it work? Values between -4 and +4 are normal; anything beyond suggests bias that needs correction.

- Real-world example: A pipe manufacturer avoided shortages by recalibrating their forecasts after spotting a tracking signal of 6.0.

Tracking signals are easy to integrate into your forecasting process and can cut costs, improve accuracy, and enhance decision-making. Let’s explore how they work and why they matter.

What Is Tracking Signal?

Definition and Purpose

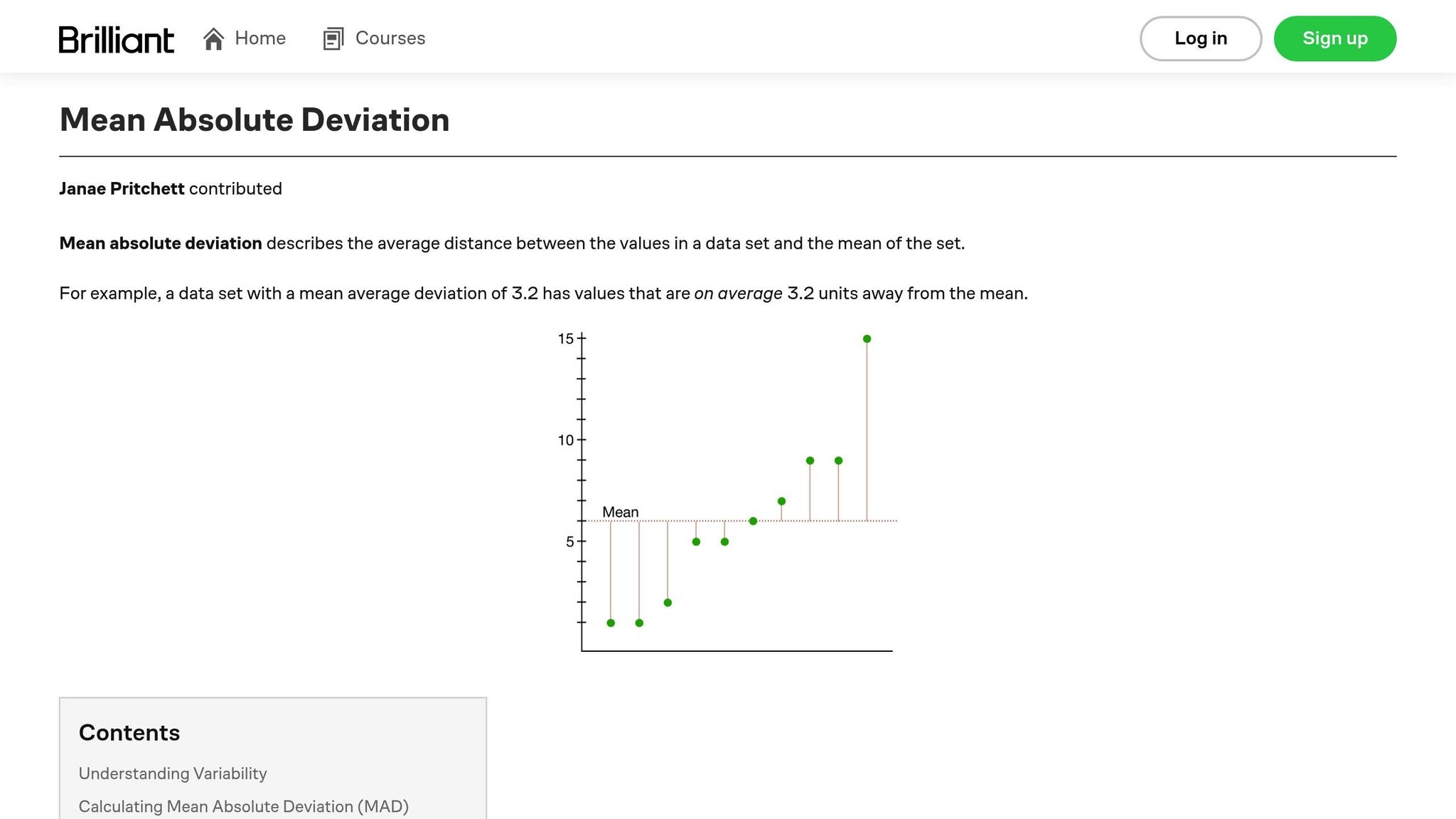

A tracking signal is a statistical tool used to identify forecast bias. It does this by comparing the ratio of cumulative forecast errors to the mean absolute deviation (MAD). While traditional error metrics focus on the size of deviations, the tracking signal highlights whether forecasts consistently lean too high or too low. Essentially, it acts as an early warning system, helping businesses spot persistent demand deviations that could lead to inventory problems.

"The 'Tracking Signal' quantifies 'Bias' in a forecast. No product can be planned from a severely biased forecast. Tracking Signal is the gateway test for evaluating forecast accuracy." – John Ballantyne

A positive tracking signal suggests that forecasts are consistently too low (under-forecasting), while a negative value points to forecasts being consistently too high (over-forecasting). Next, let’s break down how this tool is calculated and applied in real-world scenarios.

How It Works

The tracking signal is calculated by dividing the cumulative forecast errors - also known as the Running Sum of Forecast Errors (RSFE) - by the MAD. A perfectly unbiased forecast would result in a tracking signal of zero, but small deviations are expected. The key is to recognize when these deviations cross into problematic territory.

Control limits help determine when action is needed. Typically:

- Values between -4 and +4 indicate normal variation.

- Values beyond -3.75 or +3.75 suggest a bias that needs attention.

- Values exceeding -4.5 or +4.5 signal an urgent need for correction, based on a 99% service level and 3 Sigma threshold.

For instance, in June 2025, an HDPE pipe manufacturer noticed that demand consistently outpaced their forecasts. Over six months, the cumulative forecast error reached 120, with a MAD of 20. This resulted in a tracking signal of 6.0, far exceeding the 3.75 threshold. This clear under-forecasting bias prompted the company to recalibrate their forecasting model, helping them avoid potential shortages.

Calculating MAD, MAPE and Tracking Signal in Forecasting

Research Findings on Tracking Signal and Forecast Accuracy

Building on the earlier discussion about forecast bias, recent studies highlight the effectiveness of tracking signals in improving forecast accuracy and reducing errors.

Comparison of Tracking Signal Methods

Researchers have compared five tracking signal methods: CUSUM, Smoothed Error, Backward CUSUM, Autocorrelation, and Parabolic CUSUM. Among these, the Autocorrelation method stood out for its ability to minimize false alarms while accurately detecting bias.

The Smoothed Error tracking signal also performed well, particularly when an alpha value of 0.1 was used. However, its reliability declines significantly as the alpha value increases. For scenarios requiring higher alpha values, the simple CUSUM signal is often a better choice. As Everette Gardner emphasized:

"The cumulative sum of the errors appears to be the most practical forecast monitoring device."

Interestingly, research also suggests that simpler tracking signals can achieve comparable outcomes, making them an attractive option for certain applications. These comparisons provide valuable insights into how tracking signals can directly improve forecast accuracy.

How Tracking Signals Improve Forecast Accuracy

Studies reveal that tracking signals play a critical role in detecting and addressing bias before it causes operational problems.

Tracking signals not only reduce false alarms but also highlight underlying biases that need correction. Even when a tracking signal triggers a false alarm, it often points to a deeper issue within the forecasting process. As Matt Hoffman put it:

"Monitoring and eliminating bias in a planning process is huge!"

By catching bias early, tracking signals help businesses take corrective action to avoid inventory imbalances or production inefficiencies. Their ability to focus on cumulative errors allows them to uncover systematic forecasting problems that traditional accuracy metrics might miss. Companies using tracking signals report reduced forecast bias, which translates into lower inventory and production costs.

David Kloostra offered a practical perspective on their utility:

"It is a slow, reactive KPI, but one we use to re-calibrate over a period of time and tells us where we need to focus some decision making time."

Additionally, tracking signals help determine whether forecasting processes can continue as is or if intervention is needed. This ensures businesses maintain efficiency while keeping forecast accuracy within acceptable limits.

sbb-itb-97f6a47

Business Benefits of Using Tracking Signal

Tracking signals offer practical advantages for businesses, improving cost management and forecast accuracy. Companies that integrate tracking signals into their operations often see noticeable gains in efficiency and financial performance.

Cutting Costs Through Improved Forecasting

One of the standout benefits of tracking signals is their ability to reduce costs by addressing forecast bias early. Catching these biases in time helps businesses avoid expensive issues like inventory mismanagement or production delays.

A key area where savings occur is inventory management. By using tracking signals to minimize forecasting errors, companies can streamline their supply chains, allocate resources efficiently, and maintain balanced inventory levels. This not only prevents excess stock but also reduces write-offs for outdated products, keeping costs under control .

For example, in the HDPE pipe manufacturing case mentioned earlier, identifying forecast bias early enabled the company to make adjustments, preventing costly stockouts and avoiding last-minute procurement expenses.

Effective resource allocation is another cost-saving advantage. With reliable tracking signals, businesses can better plan the use of production capacity, labor, and materials. This ensures that resources are used where they’re needed most, avoiding waste and inefficiency.

These cost reductions naturally lead to a stronger focus on improving forecast reliability, which further benefits the business.

Boosting Forecast Reliability

Tracking signals play a crucial role in enhancing the accuracy of forecasts by helping businesses spot and address systematic biases before they escalate.

Bias detection and correction is central to this improvement. Tracking signals enable companies to monitor when forecasts consistently lean too high or too low, allowing them to adjust their models accordingly. This results in better inventory management, cost savings, and sustained customer satisfaction.

Supply chain expert Eman Abdelnabby highlights this importance:

"Tracking signals, therefore, are indispensable for maintaining forecast accuracy and achieving resilience in modern supply chains."

Managing demand variability becomes far easier with tracking signals. They help businesses identify unusual demand patterns or sudden shifts, enabling quicker and more strategic responses to market changes. This adaptability is especially valuable in fast-paced industries where customer needs can shift rapidly.

Informed decision-making is another benefit. Tracking signals provide actionable insights that stem from reliable forecasting methods and demand analysis. With this data, managers can make confident, strategic decisions across various parts of the organization.

Additionally, businesses can tailor their approach by setting customized tolerance levels based on their specific needs. For instance, companies with highly sensitive demand patterns might use tighter tolerance thresholds, while those with more stable demand can opt for broader ranges.

Tracking signals also offer a practical benchmark: when signals stay between -4 and +4, businesses can trust their forecasts are on track. However, if the signals exceed 3.75 or drop below -3.75, it’s a red flag that over-forecasting or under-forecasting needs immediate attention.

This improved reliability translates into better customer service as businesses can accurately meet demand and deliver on time. It also supports responsive supply chains, ensuring efficiency even in the face of market fluctuations.

Best Practices for Using Tracking Signal

Using tracking signals effectively requires a thoughtful approach. Businesses should integrate these tools into their processes in ways that fit their unique needs and operations.

Adding Tracking Signal to Forecasting Processes

To make tracking signals truly effective, they need to be part of your regular forecasting routine. This means monitoring and addressing forecast bias consistently, not just occasionally.

Automating the calculation of tracking signals is another crucial step. By setting up systems that update tracking signals as new demand data comes in, businesses can quickly spot and respond to deviations. This eliminates the delays that come with waiting for periodic reviews, like monthly or quarterly updates.

Regularly comparing forecasts to actual demand is also key. This ongoing validation helps uncover trends and patterns that might otherwise go unnoticed. When a tracking signal moves out of its acceptable range, it should prompt an immediate review of the underlying assumptions and methods used in the forecast. Clear protocols for who takes action, how quickly they respond, and the steps to investigate and fix the issue are essential.

Feedback loops are equally important for long-term success. These loops ensure that insights from tracking signal analysis are fed back into the forecasting process for continuous improvement. For instance, teams could hold regular meetings to discuss tracking signal trends or set up automated alerts to adjust forecasting models as needed.

It's also important to consider external factors - like seasonal changes, economic trends, or industry shifts - that might influence demand patterns and, consequently, the interpretation of tracking signals. By addressing these factors, businesses can select and implement tracking signals more effectively.

Choosing the Right Method

Picking the best tracking signal method depends on your business context, data, and operational needs. There's no universal solution; the method you choose should align with your specific goals, such as reducing forecast bias and improving efficiency.

The context of your forecast plays a huge role. Factors like the type of data available, the desired level of accuracy, the forecast's time frame, and the cost-benefit trade-off all influence the choice. Businesses should match their needs - whether it's accuracy, ease of interpretation, or resource availability - with the right tools.

The product life cycle also matters. For example, new products with limited historical data might require simpler approaches, while established products with extensive demand history can benefit from more advanced techniques.

Data quality is critical. Instead of opting for methods that demand high-quality but unavailable data, it's better to use techniques that make the most of what you already have. Ensuring that your data is accurate and up-to-date will directly impact how well tracking signals perform.

Simplicity often wins over complexity. Straightforward methods like moving averages can work well when historical data is limited, offering transparency and actionable insights. While more sophisticated techniques might offer higher precision, they also require more data and resources. In many cases, simpler methods strike the right balance between practicality and effectiveness.

Testing and validation are essential before committing to a method. By experimenting with different approaches on smaller data sets, businesses can find what works best for their specific needs. This trial-and-error process helps avoid relying solely on theoretical preferences.

Lastly, tolerance levels should be customized based on how sensitive your demand patterns are. For instance, businesses with highly variable demand might set wider tolerance ranges, while those with stable demand can afford narrower ones.

Once you've chosen the right method, interpreting the results accurately becomes the next crucial step.

Understanding Results in Context

Interpreting tracking signal results involves more than just looking at the numbers. It's about understanding what those numbers mean for your business operations.

For a well-rounded evaluation, combine tracking signals with metrics like MAPE (Mean Absolute Percentage Error) and MSE (Mean Squared Error). This helps paint a fuller picture of forecasting performance.

Identifying and addressing outliers is another key step. Temporary disruptions - like promotional events, supply chain hiccups, or economic shocks - can skew tracking signals. Recognizing these outliers ensures they don't lead to misinterpretations.

Balanced interpretation is critical. As David Kloostra from Mallinckrodt Pharma's Specialty Generics division explains:

"It is a slow, reactive KPI, but one we use to re-calibrate over a period of time and tells us where we need to focus some decision making time. Straight variance in units along with bias tells us more."

Continuous monitoring ensures tracking signals stay relevant. Regular analysis helps businesses spot forecast bias and demand variability as they happen, allowing for timely adjustments. This ongoing process improves forecast accuracy over time.

Context matters here, too. Combining internal and external data can clarify whether deviations are due to internal process changes, market shifts, or data quality issues. This understanding helps guide the right response.

Tracking signals also have broader applications beyond forecasting. They can provide valuable insights into other areas like customer service, inventory management, and transportation performance. This helps businesses determine whether issues stem from forecasting errors or other operational challenges.

Conclusion

Tracking signals play a crucial role in enhancing forecast accuracy and streamlining operations. As Supply Chain Professional Eman Abdelnabby explains, they help identify and address biases in demand planning, allowing companies to "maintain optimal inventory levels, reduce excess costs, and sustain customer service levels".

Studies show that keeping tracking signals within a range of –4 to +4 helps ensure forecasts remain unbiased and dependable, serving as an early warning system against potential errors. The benefits are clear: businesses can cut down on unnecessary stockpiling, allocate resources more efficiently, lower production costs, and make better decisions in areas like demand trends, marketing strategies, and inventory management.

These insights highlight the strategic importance of tracking signals in today’s forecasting processes. To implement them effectively, businesses should focus on automating their calculations, setting tolerance thresholds based on demand variability, and integrating these signals with other forecasting tools like MAPE and MSE for a well-rounded evaluation. As Peter Drucker wisely observed, "You can't improve what you don't measure", and tracking signals provide the essential metrics to shift forecasting from reactive guesswork to a strategic edge.

FAQs

How can businesses set the right tolerance levels for tracking signals to match their demand patterns?

To determine the right tolerance levels for tracking signals, businesses need to align these thresholds with their unique demand patterns and industry standards. Typically, a range of -4 to +4 is used, with values beyond this range signaling potential issues in forecasting. For instance, if signals go above +3.75 or drop below -3.75, it could point to consistent over-forecasting or under-forecasting.

By evaluating historical data and fine-tuning the tolerance range to match demand fluctuations, businesses can improve forecast accuracy. Customized thresholds help keep errors within acceptable limits, leading to smoother operations and more precise planning.

How can businesses use tracking signals to improve forecast accuracy and decision-making?

To improve the accuracy of forecasts and make smarter decisions, businesses can incorporate tracking signals into their forecasting process. A tracking signal helps identify forecast bias by dividing the cumulative sum of forecast errors by the mean absolute deviation (MAD). By setting control limits - commonly between -4 and +4 - you can spot significant deviations in forecasts. When the tracking signal goes beyond these limits, it suggests potential bias, signaling the need to review and adjust the forecasting model.

Pairing tracking signals with other metrics like Mean Absolute Percentage Error (MAPE) or Mean Squared Error (MSE) gives a broader perspective on forecast performance. Continuously monitoring these metrics and refining models based on the findings ensures ongoing improvement and builds greater confidence in business decisions.

How does a tracking signal compare to tools like MAPE and MSE for identifying and addressing forecast bias?

A tracking signal is a focused tool designed to spot and address forecast bias. By comparing cumulative forecast errors to the mean absolute deviation, it helps identify consistent patterns of over- or under-forecasting. This makes it especially useful for tackling systematic bias in predictions.

On the other hand, methods like MAPE (Mean Absolute Percentage Error) and MSE (Mean Squared Error) are geared toward assessing overall forecast accuracy. MAPE shows errors as a percentage of actual values, while MSE emphasizes larger errors by squaring them. These metrics provide a broader perspective on accuracy but are less effective at pinpointing specific bias trends.

For businesses looking to enhance decision-making and streamline operations, tracking signals serve as a precise tool to detect and correct bias, working alongside the broader insights offered by MAPE and MSE.